AEROFLEX insulation is a flexible, closed cell, and light weight elastomeric material that is made and designed for insulating liquid cooling and heating lines. The closed cell structure of AEROFLEX provides customers with so many advantages for cooling and heating line, such as moisture and vapor resistance, stable thermal conductivity during service, and many more. It is an ideal insulation for frost control and cold water plumbing. Hotel, Mall, Factory, Public and Government Office Building, and many more are the types of projects applying thermal insulation. By applying AEROFLEX, it helps to prevent the Chilled Water and refrigerant pipelines copper tubes to condense and freeze, furthermore, it also helps to prevent heat loss from hot water plumbing, liquid, and dual temperature piping.

I. AEROFLEX® Specifications

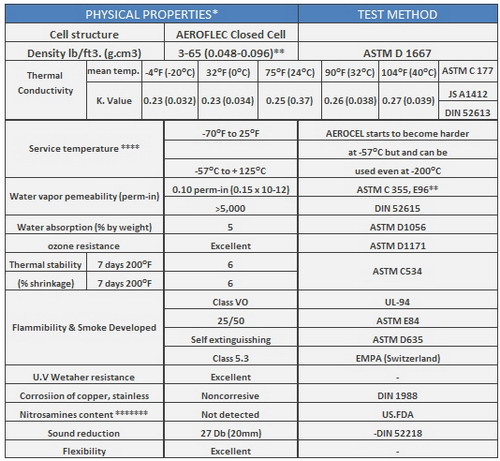

Specifications Comply with ASTM C534-88

- Figures show the average values obtained by the world well-known testing institues.

- Test according to DIN, JIS ASTM and others.

- Average density of insulation thickness over 20 mm.

- At temp. Under -57°C AEROFLEX becomes hard, but it doesn’t effect thermal conductivity nor water vapor permeability. In the heating applications AEROFLEX can stand +125°C continuously, and the adhesive upto +100°C

- Water vapor permeability test was done under test method ASTM E96 Dehydrate test method at 37.8°C

- IMO: International Maritime Organization. IMO fire test procedures code part 5 and part 2 (IMO res. A 653 (16)).

Lloyd’s Type Approval Certificate

DNV’s Type Approval Certificate - It is reported that Nitrosamine is harmful to human health even during storage. No Nitrosamine compound was detected in AEROFLEX.

II. AEROFLEX® Characteristics and Advantages

III. Product Applications

a. Hot Water Piping

b. Chilled Water Piping

c. Ducting System